Pressure vessel production with HP Multi Jet Fusion

industrialpartners offers its customers the most innovative processes for the production of small and

medium-sized series of parts. In addition to conventional injection molding, we also use the latest 3D printing processes – such as HP’s Multi Jet Fusion technology (MJF) – to produce our parts.

This revolutionary 3D printing process has many advantages to offer over conventional laser sintering. Parts produced with HP MJF have a higher density, an erosion-like surface structure and can be manufactured in the shortest production times.

For you, this means: no-series production of plastic parts and assemblies on an industrial scale at attractive prices!

To expand our range of products and services, we have now conducted an internal study to determine whether it is possible to produce pressure vessels with HP MJF in an economically viable manner. Our question in this study was therefore: “Is the HP Multi Jet Fusion manufacturing process suitable for the production of tanks that are exposed to high internal pressure?”

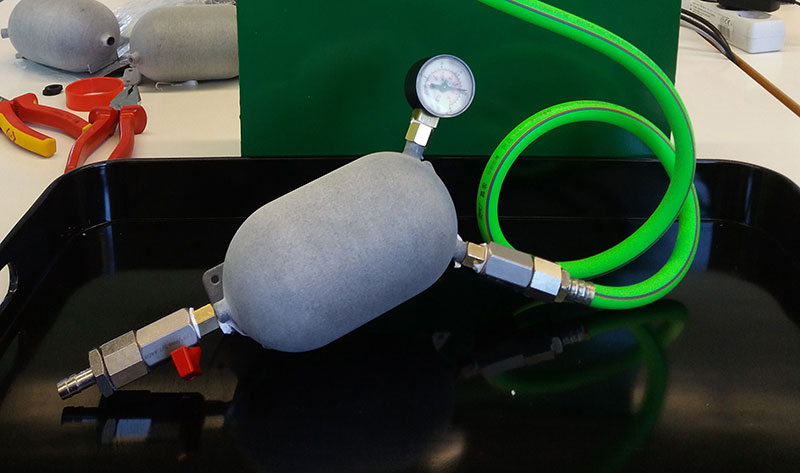

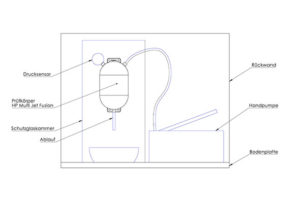

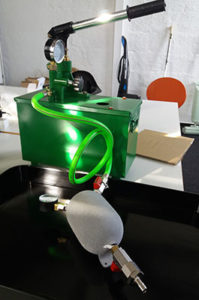

To this end, we produced a number of tanks and then tested the resulting tanks. For the pressure-tightness test, the test specimens produced with HP MJF were filled with water and permanently pressurized to 20 bar for four months using a hand pump.

The result is astonishing for an additive manufacturing process: No moisture leakage and no pressure loss – even over a long period of time!

If one compares pressure vessel production with HP MJF with other processes, in which, for example, conventional vessels are produced from metal or conventional plastic manufacturing processes, there are significant advantages for this process:

With HP MJF, tanks can be manufactured in any shape (such as spherical, cylindrical or cube-shaped) that guarantees high wear resistance and thus usability on an industrial scale. The pressure vessels produced in this way can be used for different pressure ranges depending on the wall thickness dimensioning. Due to the process-related easy scalability, freely selectable shape design and the possibility to integrate different coupling pieces in one production step, the production of e.g. shape-complex tanks and pressure vessels is no longer a problem at all. In addition, pressure vessel production with HP MJF as an alternative to conventional processes even remains comparatively inexpensive!

A separate study by HP also demonstrated that parts produced by the MJF process have a higher density (1.01 g/cm³) than parts produced by the conventional laser sintering process (0.90-0.95 g/cm³). The polyamide HD 3D PA 12 used in the MJF also has much lower porosity than, for example, the SLS PA 12 material commonly used in the laser sintering process. It enables the production of ultra-thin layers of only 80 micrometers and thus excellent detail fidelity, as well as outstanding surface quality. It also scores in terms of chemical resistance: Even hot water, alcohol, aliphatic hydrocarbons (gasoline components included), engine oil, as well as DOT-3 brake fluid cannot harm the PA 12 material used by Multi Jet Fusion. But that’s not all: the pressure vessels created with HP MJF have also passed IP66 and IP67 tests.

In summary, HP has revolutionized pressure vessel production with the Multi Jet Fusion process and we are proud to offer our customers this new technology.

are proud to be able to offer this new technology to our customers!

For further information, two documentations are available.

Please contact Mr. Jens Arend at j.arend@hk.systems